What is the manufacturing process of hydrated lime

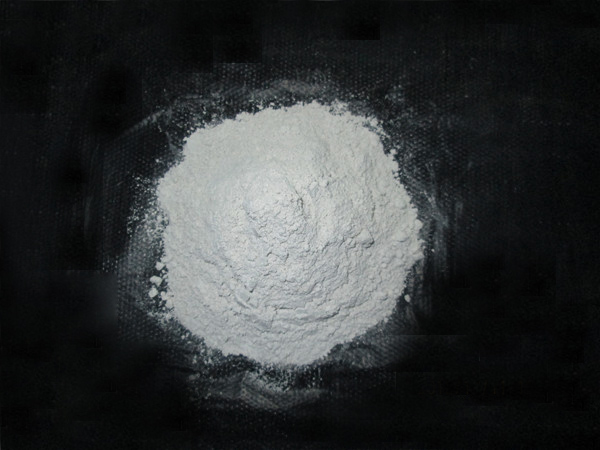

Hydrated lime, also known as calcium hydroxide or slaked lime, is a fine white powder that is produced by mixing calcium oxide (quicklime) with water. The chemical formula of hydrated lime is Ca(OH)2.

Hydrated lime has several important properties, including high alkalinity, high reactivity, and good solubility in water. These properties make it useful in a wide range of industrial, agricultural, and environmental applications, including:

Water treatment: Hydrated lime is used to adjust the pH of water and remove impurities, such as heavy metals and organic matter.

Soil stabilization: Hydrated lime is added to soil to improve its stability, reduce plasticity, and increase compressive strength.

Flue gas treatment: Hydrated lime is used to remove sulfur dioxide and other pollutants from flue gases produced by power plants and industrial facilities.

Waste treatment: Hydrated lime is used to treat wastewater and solid waste to reduce odors, improve stability, and reduce pathogens.

Construction: Hydrated lime is used as a binding material in mortar and stucco and as a filler in paint and other products.

In addition to its industrial uses, hydrated lime is also used in food processing, pharmaceuticals, and other industries. Its production process mainly includes the following steps:

1. Limestone Quarrying: Limestone is quarried from the ground and transported to a plant for further processing.

2. Calcination: Limestone is calcined (heated) in a kiln to produce quicklime (calcium oxide). The temperature in the kiln is usually around 900 to 1,200°C.

3. Slaking: Quicklime is mixed with water in a reactor to produce hydrated lime (calcium hydroxide). The slaking process generates heat and can take several hours to complete.

4. Milling: The hydrated lime slurry is then milled to produce a fine powder. This can be done using various milling techniques, including ball milling, roller milling, and impact milling.

5. Classification: The milled hydrated lime powder is classified to separate particles of different sizes and remove any oversize particles.

6. Packaging: The hydrated lime powder is then packaged in bags or containers for transportation and storage.

The quality of hydrated lime is influenced by several factors, including the quality of the raw limestone, the efficiency of the calcination process, and the conditions during the slaking and milling processes. Hydrated lime is used in a variety of industrial, agricultural, and environmental applications, including water treatment, soil stabilization, and flue gas treatment.