Calcium Hydroxide Adsorbent

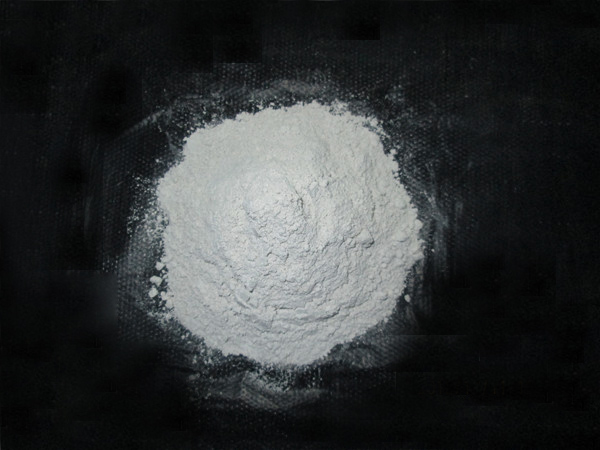

Calcium hydroxide, also known as slaked lime or hydrated lime, is a chemical compound that has been studied as a potential sorbent for carbon dioxide (CO2) capture. It is a white, crystalline powder that is soluble in water and has a relatively low cost compared to other sorbents.

The sorption process with calcium hydroxide involves passing a gas stream containing CO2 through a bed of the sorbent material. The CO2 reacts with the calcium hydroxide to form calcium carbonate, which can be collected and stored or utilized. The sorbent can then be regenerated by heating, which releases the captured CO2 and regenerates the calcium hydroxide for reuse.

One advantage of using calcium hydroxide as a sorbent is its low cost and availability. Calcium hydroxide is a widely used industrial chemical and can be produced from inexpensive raw materials, such as limestone.

Calcium hydroxide, also known as slaked lime or hydrated lime, is a chemical compound that has been studied for its potential as a carbon dioxide adsorbent.

Calcium hydroxide is a white, crystalline powder that is soluble in water. When exposed to carbon dioxide, it reacts to form calcium carbonate, which is a stable, solid compound. This reaction can be used to capture carbon dioxide from gas streams, such as flue gas from power plants or industrial processes.

The adsorption process with calcium hydroxide involves passing the gas stream through a packed bed or fluidized bed of the material. The carbon dioxide reacts with the calcium hydroxide to form calcium carbonate, which can be collected and stored or utilized.

One advantage of using calcium hydroxide as a carbon dioxide adsorbent is its low cost and availability. Calcium hydroxide is a widely used industrial chemical and can be produced from inexpensive raw materials, such as limestone.

However, calcium hydroxide also has some limitations as an adsorbent, including a relatively low carbon dioxide adsorption capacity compared to some other materials. Additionally, the reaction with carbon dioxide is exothermic, meaning that heat is released during the reaction, which can cause temperature increases in the adsorbent bed and limit its use in certain applications.

The process flow for using calcium hydroxide as a carbon dioxide adsorbent typically involves the following steps:

- Preparation of the adsorbent: Calcium hydroxide is typically prepared by slaking quicklime (calcium oxide) with water. The resulting slurry is then dried and milled to produce a fine powder.

- Preparation of the gas stream: The gas stream containing carbon dioxide is typically pre-treated to remove any impurities, such as sulfur dioxide or nitrogen oxides. This can be done using various methods, such as scrubbing or catalytic conversion.

- Adsorption: The pre-treated gas stream is then passed through a packed bed or fluidized bed of calcium hydroxide powder. As the gas stream comes into contact with the calcium hydroxide, a chemical reaction occurs, in which the carbon dioxide reacts with the calcium hydroxide to form calcium carbonate. This reaction results in the capture of the carbon dioxide from the gas stream.

- Carbon dioxide release: Once the calcium hydroxide has adsorbed a sufficient amount of carbon dioxide, the adsorbent bed is typically heated to release the captured carbon dioxide. This regeneration step involves the reverse reaction of calcium carbonate and calcium oxide formation. The released carbon dioxide can be collected, stored, or utilized.

- Repeat the process: The regenerated calcium hydroxide can then be reused in subsequent cycles of adsorption and carbon dioxide release.

The calcium hydroxide has potential as a sorbent for CO2 capture, particularly in applications where low cost and availability are important considerations. However, its performance needs to be evaluated and optimized for specific applications, and it may be best suited for smaller-scale applications, such as point source emissions from industrial processes or power plants.