How to check whether calcium hydroxide has deteriorated? Inspection methods and reasons for deterioration

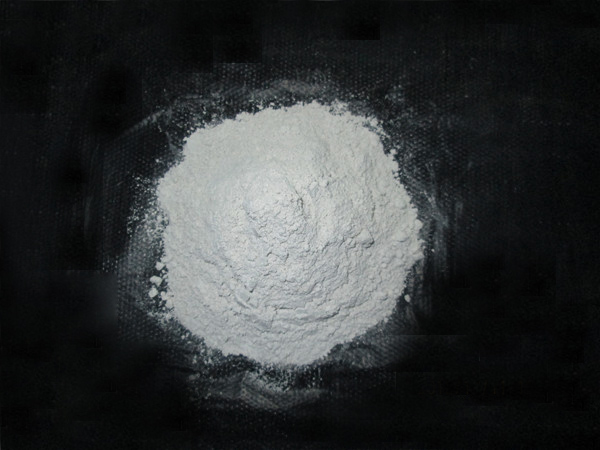

Calcium hydroxide is widely used in industrial production and life, but we often find that the effect of calcium hydroxide in use is not in line with the routine, so the deterioration of calcium hydroxide has become a problem that needs urgent attention. How to test calcium hydroxide Whether it has deteriorated, and the reasons for the deterioration of calcium hydroxide, we have introduced the following details, let’s find out together!

Identification method of calcium hydroxide deterioration

1. Hydrochloric acid identification method

Take out some calcium hydroxide and add enough hydrochloric acid. If there is gas, it means that the calcium hydroxide has deteriorated.

2. Water identification method

Another method introduced by calcium hydroxide manufacturers is that after adding sufficient water, there are still insolubles, which also means that calcium hydroxide has deteriorated, because calcium carbonate is insoluble in water.

3. Carbon dioxide identification method

Calcium hydroxide is easily hardened with carbon dioxide in the air to form calcium carbonate. Therefore, we only need to determine whether there is calcium carbonate in the calcium hydroxide powder to know whether it has deteriorated.

Reasons for the deterioration of calcium hydroxide

1. The temperature is too high

The reason for the deterioration is temperature, and increasing the temperature can cause thermal cracking or thermal cross-linking of calcium hydroxide. But the basic effect of heat is activation. Improve the oxygen diffusion rate and activate the oxidation reaction, thereby accelerating the oxidation reaction rate of calcium hydroxide, which is a common aging phenomenon – thermal oxygen aging

2. Air contact

In the storage and transportation of calcium hydroxide, if it is exposed to the air for a long time, oxygen will react with the rubber molecules in the calcium hydroxide free radical chain reaction, and the molecular chain will be broken or excessively cross-linked, which will cause the change of rubber properties. Oxidation is one of the important reasons for rubber aging. There is also ozone in the air, the chemically active oxygen of ozone is much higher and more destructive, it also breaks the molecular chain, but the effect of ozone on calcium hydroxide varies with whether the rubber is deformed or not. When used as a deformed rubber reinforcing agent, cracks that are straight in the direction of stress action, the so-called “ozone cracks”, appear.

3. Ultraviolet rays are too high

Stored in the open air, the shorter the light wave, the greater the energy. What destroys calcium hydroxide is ultraviolet rays with higher energy. In addition to the direct rupture and cross-linking of the rubber molecular chain caused by ultraviolet light, calcium hydroxide generates free radicals by absorbing light energy, which initiates and accelerates the oxidation chain reaction process. The external light plays a role in heating. Another feature of the light effect is that it mainly grows on the surface of the oak. For samples with high glue content, there will be network cracks on both sides, that is, the so-called “optical outer layer cracks”. Factors that cause calcium hydroxide aging include chemical media, variable valence metal ions, high-energy radiation, electricity, and biology.

The above is the answer to the question of how to check whether calcium hydroxide has deteriorated. Knowing the reason for the deterioration can effectively prevent the deterioration of calcium hydroxide and ensure the quality of calcium hydroxide. Calcium hydroxide is transported separately during the transportation process to avoid mixing with acids, inflammables, organics, etc., to ensure the quality of calcium hydroxide.